• Different types of Master Data in SAP MM are: -

1. Material Master

2. Vendor Master

3. Info Records

4. Source list

5. Quota Arrangement

Material: - The goods that are subject of business activities. The material can be traded, used in manufacture, consumed, or produced

Material Master: -

It is a Master file which contains information of a particular material, depending upon the views selected from the user departments.

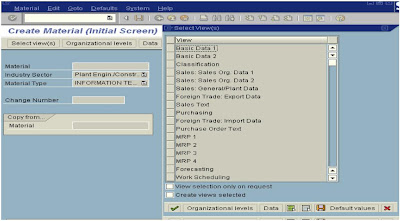

• Different types of views available in Material Master Record are

1. Basic data 1 & 2

2. Purchasing

3. General plant data storage 1 & 2

4. Warehouse Management 1 & 2

5. MRP (Material required planning) 1,2,3,4

6. Accounting 1 & 2

7. Costing 1 & 2

8. Quality Management

9. Plant Stock

10. Storage Location Stock

11. Classification

12. Forecasting

13. Purchase Order Text

14. Foreign Trade: Import Data

Material Type: -

It is a key that assigns the material to a group of materials such as Raw materials, trading goods. This allows you to manage different materials in a uniform manner in accordance with your company's requirements.

The Material type defines certain attributes of the material and has important control functions.

UseWhen creating a material master record, the material type determines

• Whether the material number is assigned internally or externally

• From which number range interval the material number comes

• Which screens are displayed

• The order in which screens are displayed

• Which department-specific data is displayed for the user to enter

Different Material Types available: -ROH - Raw Material

FERT - Finished Product

HALB- Semi finished Product

HAWA- Trading goods

DIEN - Services

ERSA - Spare Parts

PIPE - Pipeline material

LEIH - Returnable Packaging

HERS- Manufacturer Parts

FGTR - Drinks

FOOD- Foods

FRIP - Perishable Goods

Configurable materials (KMAT): Configurable materials are materials that can have different variants. For example, an automobile can have different types of paintwork, trim, and engine.

Finished products (FERT): Finished products are produced in-house. Since they cannot be ordered by Purchasing, a material master record of this material type does not contain purchasing data

Non-stock materials (NLAG): Non-stock materials are not held in stock because they are consumed immediately.

Non-valuated materials (UNBW): Non-valuated materials are managed on a quantity basis, but not by value.

Packaging materials (VERP): Packaging materials are used to transport goods and come with the goods free of charge. A material master record of this material type is managed on both a quantity basis and value basis.

Pipeline materials (PIPE): Materials such as oil, power, or water that flow into the production process directly from a pipeline, line, or other type of conduit. Since pipeline materials are always available, they are not planned.

Raw materials (ROH): Raw materials are always procured externally and then processed. A material master record of this type contains purchasing data, but not sales data since they cannot be sold.

Semi finished products (HALB): Semi finished products can be procured externally and manufactured in-house. The company then processes them. A material master record of this material type can contain both purchasing and work scheduling data.

Services (DIEN): Services can be performed internally or procured externally (outsourced). They cannot be stored or transported.

Spare parts (ERSA): Spare parts are used to replace defective parts. They may be kept in stock. A material master record of this material type can contain purchasing data, but not sales data.

Trading goods (HAWA): Trading goods are always procured externally and then sold. A material master record of this material type can contain purchasing data and sales data.

Material Group: -T Code WG21Key that you use to group together several materials or services with the same attributes, and to assign them to a particular material group.

SPRO �� IMG �� Logistic General �� Material Group �� Create Material Group

Price Control: - Two types of Price Controlled given by SAP

1. Moving Price – ‘V’

2. Standard Price- ‘S’

Standard Price:1. Valuation using a standard price has the following features:

2.All inventory postings are carried out at the standard price.

3. Variances are posted to price difference accounts

4. Variances are updated

5. Price changes can be monitored

If a material is assigned a standard price (S), the value of the material is always calculated at this price. If goods movements or invoice receipts contain a price that differs from the standard price, the differences are posted to a price difference account. The variance is not taken into account in valuation.

Moving Average Price:Valuation using a moving average price results in the following:

• Goods receipts are posted at the goods receipt value.

• The price in the material master is adjusted to the delivered price.

• Price differences occur only in exceptional circumstances.

If a material is assigned a moving average price (MAP), the price is automatically adjusted in the material master record when price variances occur. If goods movements or invoice receipts are posted using a price that differs from the moving average price, the differences are posted to the stock account; as a result, the moving average price and the value of the stock change

Valuation Class: - (For creation T Code OMSK)It is used to determine which stock account is updated during the goods movement of a material. It is maintained inAccounting 1 view in material master record.

For material type ROH take valuation class as 3000, 3001, 3002, 3003

For material type HAWA take valuation class as 3100, 3010

For material type FERT take valuation class as 7920.

For material type HALB take valuation class as 7900. 7910

For material type DIEN take valuation class as 3200

For material type ERSA take valuation class as 3040

Number Ranges: -Number ranges are maintained for each & every document, Posted in the SAP System. The maximum numbers of digit allowed are 18digits (99, 9999, 9999, 9999, and 9999).

Two types of number ranges: -

Internal number ranges - System will automatically define numbers to all documents

External number ranges - User has to give doc number externally while creating document.

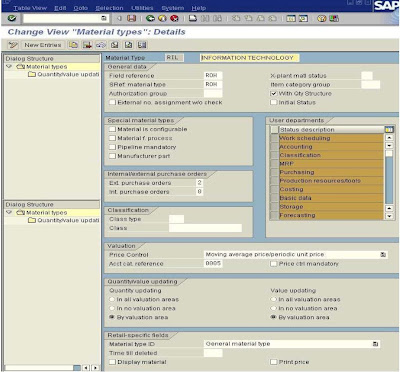

Customize settings for creating Material Types: -SPRO�� SAPIMG �� Logistics General ��Material Master �� Basic Settings �� Material Type

• Define Attributes of Material Type

• Define Number Ranges for Each Material Type

• Define Attributes of Material Type

Select the material type e.g. ROH �� click on copy button

Change the Material Type from ROH to say RIL (Information technology)

Keep External Number Assignment without check

Press Enter �� Save

{Account Category Reference: - It is group of valuation classes

Item Category Group: - Group of material that the system uses to determine item category for the processing of sales document.}

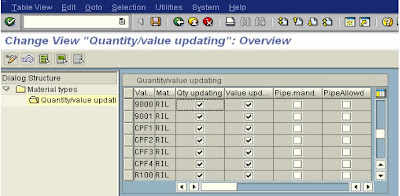

Again select the material type & click on Quantity / value updating (left side)

Select the valuation area or Plant along with newly created Material type.

Activate / select Quantity updating or Value updating.

Valuation area: - Organization level at which material valuation is carried out

Then Save.

• Define Number Ranges for each Material Type

Click on Groups (Maintain) – F6

Click on Groups (Menu bar) �� Insert

Write some text

Give number from _____ to ______.

Select the Material Types newly created.

Click on select element (F2)

Select the group & click on Element / Group

Save.

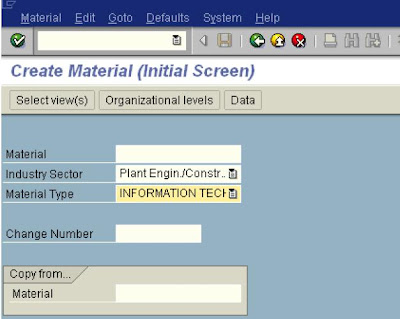

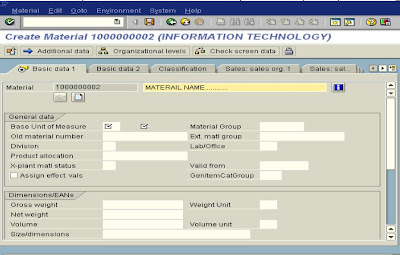

To Create a Material MasterTransaction code: -

MM01: To create & to extend the material

MM02 :To change / edit

MM03 :To display

MM06 :To deletes the Material master

MM50 :To extend the Material views

MM60 :To See Material Master List

MMAM : To Change the Material Type

• Path of - MM01SAP Easy Access �� Logistics �� MM �� Material Master �� Material �� Create General

• To Create Material Master: - Transaction Code: - MM01

Select Industry Sector & Material Type �� Press Enter

When you create a material master record, you are required to classify the material according to industry sector and material type.

Industry SectorKey that specifies the branch of industry to which the material is assigned

Use: When you create a material master record, the industry sector determines

• Which screens appear and in what order

• Which industry-specific fields appear on the individual screens

Then Click on Organization levels select Views & Press Enter

Enter Plant & Storage Location then Press Enter

Enter all the required fields in different Views (Basic data1, Sales, Accounting etc)

After entering all the fields Press enter and Save

Fields in different views in Material Master• Basic Data 1Material Description

Basic Unit of Measure

Material Group

Old Material Number

X- Plant Material Status- Blocking option

General item category

Gross Weight

Net Weight

Volume etc

• Basic Data 2 – contains Design Drawing information

• PurchasingBasic unit of measure

Purchasing Group

Material Group

Plant – Specific – Material Status - Blocking option

Source list

Batch Management – Automatic PO

Purchasing value key

GR Processing time (number of days required after receiving a material for inspection & then placed into the storage location)

Critical Part

Manufacturer Part number

Manufacturer

• General Plant Data Storage 1: -Basic Unit of measure

Temperature conditions

Storage Conditions

Container Requirements

Hazards material number

Batch Management

SLED (Shelf Life Expiration Date)

• General Plant Data Storage 2: -

Plant

Gross weight

Net Weight

Negative stock in plant

Profit Center

• Accounting 1: -Basic Unit of Measure

Valuation Class

Price control

Price unit

Valuation Category

Currency

Moving & Standard Price

Total Stock

Total Value

Division

• Accounting 2

Tax Price 1,2,3

Commercial Price 1,2,3

LIFO Pool

• Work SchedulingUnit of issue

Production unit

Plant specific material status

Tolerance data

Material group

Batch management

Base quantity

• Quality management

Unit of issue

GR processing time

Plant specific material status

QM Control key

QM procurement active

No comments:

Post a Comment

Note: only a member of this blog may post a comment.